Yes! A plastic On3 Precision Scale Shay! I picked this up for a steal on eBay a few years ago thinking, well, if it doesn't work I at least get a Falhaulber 50:1 motor. I recently completed another GrandtLine Porter, this one for On30 and had such a fun time assembling it that figured it would be a great time to try my hand at this project. The Porter is disassembled in the paint shop, photo's eventually.......

Generally, (note not always) the instructions are excellent. You definitely want to read a few steps ahead to see what else they say before doing anything. The trucks are the first assembly. I found them easy to construct, using plastic model building techniques. Make sure you don't make a mistake with alignment or parts orientation as you don't want to have to take them apart (there's no way to unsolder as with brass). The person I bought the kit from had started the trucks and made a MESS. They used ACC glue instead of a plastic specific glue. Knowing this, I ordered some new side frames from PSC before they changed hands. You'll note in the picture that I started the frame at the same time. One thing about plastic models, you often have to really wait till the glue has dried completely before proceeding, therefore, I had two to three components being assembled at the same time. Glue a part, move to the next assembly, etc.

Here are some of the sub-assemblies moving along nicely. I added a Wisemann Model Services sand dome as most of this sized shay had the more modern domes.

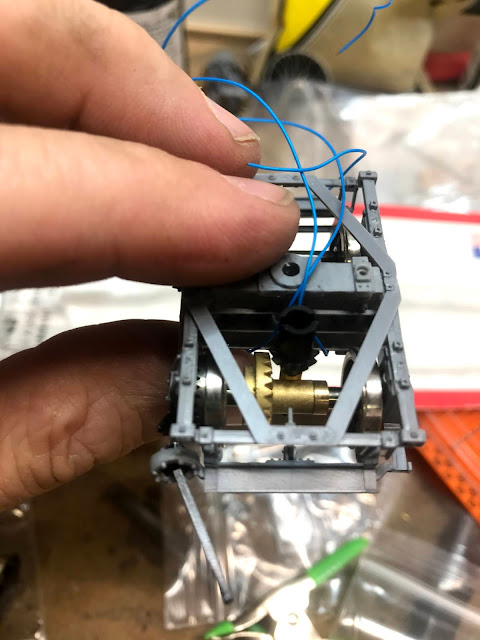

Note the large gap between the gears. The small brass mounting does not have the plastic gear centered, it is slightly off centered and needed to be mounted the OTHER WAY! But wait, this model was GLUED together.......

So, I carefully added some solvent glue to the cross bracing, brake hanger and bottom tie hoping I could remove the drivers without braking the whole thing. Well, all those little hanger broke, but sheared off, which meant I could glue them on again and hope for the best; however, the main bolster and rest of the truck stayed together. After disassembling, pulling the driver, re-orienting the drive, I put it all back together and IT WORKS! I'm happy that it worked but was I not happy that I trusted the folks who put these together at PSC, maybe they contracted that to someone......

So, plastic shay a good idea? Hmm, easy to build using typical plastic model building skills. Build a model tank or something first. A few problems: plastic breaks easily. The frame is very flexible. There is little weight but lots of room to add weight. I added lead bird shot in the boiler and some small lead strip in the truck bolsters. The hardest parts to build - the fine detail with the eccentrics for the engine was tough. One of my eccentrics had a broken tab, making the fit impossible. I drilled and glued a brass rod on but it wasn't fun. The second hardest part - the universals that attach to the engine. The ones for the trucks were easy but the ones for engine were a bear.........

These originally sold for $275, if you can find one, it's worth the build. I wouldn't pay more unless you are a real fan of this engine. Save up and get a brass one. Once I get this painted, DDC, sound and lights, I'll post on it's running qualities.

Cheers!

No comments:

Post a Comment